gam PURmungkin kelihatan lebih mahal daripada pelekat tradisional, ia mempunyai kekuatan ikatan yang jauh lebih tinggi dan memerlukan lebih sedikit bahan bagi setiap penggunaan. Apabila digabungkan dengan XingmingdaMesin Pembalut PURgaris, ia menghasilkan kemasan yang lebih licin, penundaan minimum dan kadar sekerap yang jauh lebih rendah — kelebihan kos yang jelas dari semasa ke semasa. Dalam banyak kes, pelanggan telah melaporkan memulihkan pelaburan mereka dalam tempoh enam bulan selepas pemasangan.Fleksibiliti untuk PKS: Penyelesaian Separa Automatik dan Tersuai

Xingmingda memahami bahawa tidak setiap PKS boleh segera beralih kepada automasi penuh. Oleh itu, syarikat itu menawarkan penyelesaian berskala — daripada separa automatik

Mesin Profil PUR Lebar 300mm

kepada automatik sepenuhnya1300 Mesin Pembalut PUR. Setiap mesin boleh disesuaikan berdasarkan susun atur bengkel pelanggan, jumlah pengeluaran dan jenis produk.Selain itu, reka bentuk modular

Mesin Pembalut Panel PUR 600mm

danMesin Panel PUR Lebar 400mmmembolehkan perubahan acuan mudah dan operasi satu klik. Ini membolehkan pengeluar bertukar antara bahan dan kemasan yang berbeza dalam beberapa minit — ciri yang sangat berharga untuk pengeluar perabot tersuai dan pembekal panel seni bina yang mengendalikan pelbagai pesanan setiap hari.

Kisah Pelanggan: Dari Sepanyol kepada KejayaanContoh jelas datang daripada pengeluar pintu kabinet Sepanyol yang memutuskan untuk menaik taraf daripada laminasi manual kepada automatikMesin Pembalut PUR

sistem yang dibekalkan oleh Xingmingda. Dalam masa enam bulan sahaja, syarikat bukan sahaja mengurangkan kos buruh sebanyak 40% tetapi juga meningkatkan kestabilan keluaran dan konsistensi produk. Pelaburan itu membayar sendiri lebih cepat daripada jangkaan, menunjukkan bahawa kilang-kilang kecil juga boleh menikmati dividen automasi industri.Beyond Machinery: Perkhidmatan, Kebolehpercayaan dan PerkongsianDi sebalik setiap mesin terletak komitmen Xingmingda terhadap kecemerlangan perkhidmatan. Rangkaian jualan dan teknikal syarikat meliputi pasaran domestik dan antarabangsa, memastikan sokongan selepas jualan tepat pada masanya. Program latihan yang kerap membantu meningkatkan kepakaran kakitangan, mengukuhkan kepercayaan bahawa "reputasi yang baik datang daripada kualiti yang tahan lama, boleh dipercayai dan boleh dipercayai."

Dengan menggabungkan pengurusan moden, ketukangan mahir, dan inovasi berorientasikan pelanggan, Xingmingda telah berubah daripada pembekal peralatan tempatan kepada pemain global yang diiktiraf sebagai boleh dipercayai.Mesin Pembalut PUR.

Kesimpulan: Laluan Baharu untuk PKS GlobalPada zaman pembuatan pintar, keupayaan untuk mengawal kos sambil meningkatkan kecekapan pengeluaran mentakrifkan daya saing. Untuk PKS di seluruh dunia, bekerjasama dengan pengeluar China sepertiFoshan Xingmingda Automatic Woodworking Machinery Co., Ltd.

menawarkan laluan ketara ke arah automasi — tanpa melebihkan belanjawan.

daripada

Mesin Pembalut Panel PUR 600mmkepadaMesin Pembalut 1300 PUR, setiap produk mewakili komitmen untuk membantu perusahaan berkembang maju di tengah-tengah ketidakpastian. Dalam dunia di mana kecekapan adalah kelangsungan hidup dan inovasi adalah pertumbuhan, buatan ChinaMesin Pembalut PURbukan lagi alternatif - ia adalah penyelesaiannya.

This factory-direct wholesale model, combined with flexible customization services, ensures that customers receive the equipment that best suits their production needs with minimal investment.

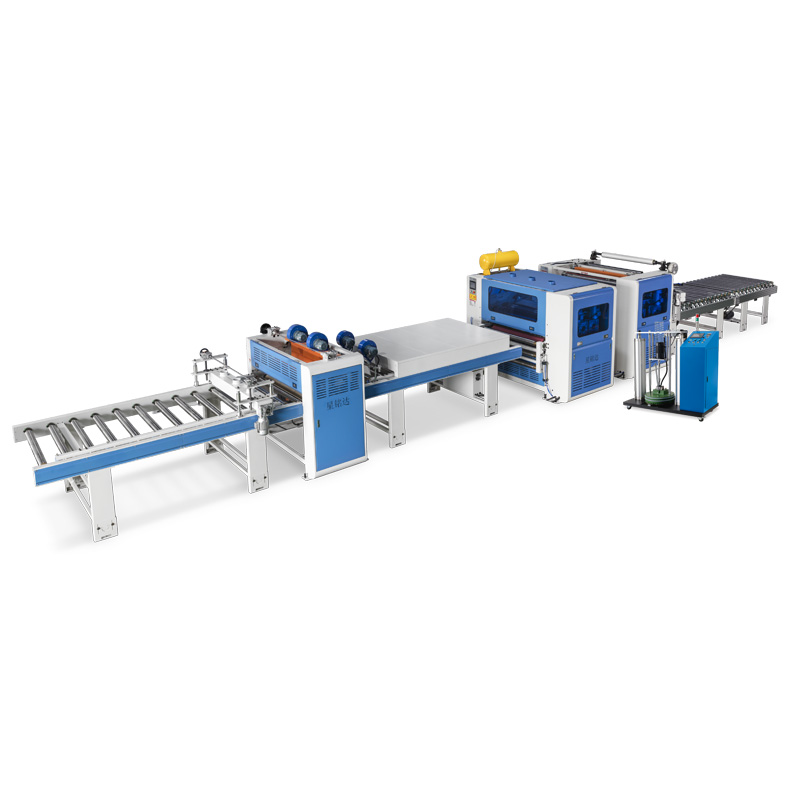

In recent years, global inflation and economic uncertainty have created immense pressure on manufacturing enterprises, particularly small and medium-sized enterprises (SMEs). The dual challenges of rising raw material costs and labor shortages have forced many companies to seek new paths toward automation and cost optimization. Against this backdrop, Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd., a professional manufacturer located in the “Town of Woodworking Machinery” — Lunjiao, Shunde, Foshan — is emerging as a trusted partner for global SMEs. With products such as the 600mm PUR Panel Wrapping Machine, 300mm Width PUR Profile Machine, 400mm Width PUR Panel Machine, and 1300 PUR Wrapping Machine, the company provides PUR Wrapping Machines that deliver both efficiency and long-term value.

Global Challenges: Efficiency and Cost Pressure Collide

Across Europe, Southeast Asia, and the Americas, SMEs are navigating a tough business environment: fluctuating orders, limited skilled labor, and intense competition from automation-driven factories. While large enterprises can afford to invest heavily in high-end equipment, SMEs must balance performance, price, and return on investment (ROI) — a balancing act that has never been more critical.

This is where China’s PUR Wrapping Machine manufacturers step in. Far from the outdated notion of “low cost means low quality,” today’s Chinese automation equipment offers a rare combination of technological innovation, stable performance, and affordable pricing, helping global partners achieve efficient and flexible production at reasonable cost.

The Xingmingda Advantage: Cost-Effective Automation, Made in China

Founded in 2004, Foshan Xingmingda has spent over two decades specializing in the research, design, and production of PUR lamination machines, wrapping machines, edge banding machines, and slotting machines. The company’s philosophy — “Quality first, customer satisfaction, continuous innovation” — runs through every stage of manufacturing. From R&D to quality control, Xingmingda integrates precision CNC equipment and adopts advanced management systems to ensure product consistency and durability.

The 600mm PUR Panel Wrapping Machine and 400mm Width PUR Panel Machine have become the company’s star products, designed for high-performance coating and laminating on MDF, PVC, and aluminum profiles. Meanwhile, the 300mm Width PUR Profile Machine and 1300 PUR Wrapping Machine cater to customized panel sizes, allowing clients to achieve both flexibility and productivity. Collectively, these PUR Wrapping Machines help small and medium workshops move toward automation with minimal risk and maximum gain.

High Value ≠ Low Cost — Understanding True ROI

One of the biggest misconceptions about Chinese equipment is that “affordable” equals “cheap.” Xingmingda’s approach challenges this bias. The company emphasizes that high value comes not from cutting corners but from intelligent cost structure — lower waste rates, less downtime, and longer lifespan per machine.

For example, while PUR glue might appear more expensive than traditional adhesives, it has significantly higher bonding strength and requires much less material per use. When combined with Xingmingda’s PUR Wrapping Machine line, it results in smoother finishes, minimal delamination, and far lower scrap rates — a clear cost advantage over time. In many cases, clients have reported recovering their investment within six months of installation.

Flexibility for SMEs: Semi-Automatic and Custom Solutions

Xingmingda understands that not every SME can immediately transition to full automation. Therefore, the company offers scalable solutions — from semi-automatic 300mm Width PUR Profile Machines to fully automated 1300 PUR Wrapping Machines. Each machine can be customized based on the client’s workshop layout, production volume, and product type.

Moreover, the modular design of the 600mm PUR Panel Wrapping Machine and 400mm Width PUR Panel Machine enables easy mold changes and one-click operation. This allows manufacturers to switch between different materials and finishes within minutes — a feature especially valuable for custom furniture producers and architectural panel suppliers who handle diverse orders daily.

Customer Story: From Spain to Success

A vivid example comes from a Spanish cabinet door manufacturer who decided to upgrade from manual lamination to an automated PUR Wrapping Machine system supplied by Xingmingda. Within just six months, the company not only reduced labor costs by 40% but also increased output stability and product consistency. The investment paid for itself faster than expected, demonstrating that small factories can also enjoy the dividends of industrial automation.

Beyond Machinery: Service, Reliability, and Partnership

Behind every machine lies Xingmingda’s commitment to service excellence. The company’s sales and technical network covers domestic and international markets, ensuring timely after-sales support. Regular training programs help enhance staff expertise, reinforcing the belief that “good reputation comes from durable, reliable, and credible quality.”

By combining modern management, skilled craftsmanship, and customer-oriented innovation, Xingmingda has transformed from a local equipment supplier into a global player recognized for dependable PUR Wrapping Machines.

Conclusion: A New Path for Global SMEs

In the age of intelligent manufacturing, the ability to control costs while boosting production efficiency defines competitiveness. For SMEs worldwide, partnering with a Chinese manufacturer like Foshan Xingmingda Automatic Woodworking Machinery Co., Ltd. offers a tangible route toward automation — without overextending budgets.

From the 600mm PUR Panel Wrapping Machine to the 1300 PUR Wrapping Machine, every product represents a commitment to helping enterprises thrive amid uncertainty. In a world where efficiency is survival and innovation is growth, Chinese-made PUR Wrapping Machines are no longer an alternative — they are the solution.